WASTEWATER TREATMENT PLANT CONCRETE TANKS RECOATING

Location

Saudi ArabiaTotal Area

6,000 m² @ 3mmCoating System

DELTAPrime 2K SF

DELTAPrime Filler

DELTAShield HP 400

Client

Global Environmental Management ServicesDate

2017Summary

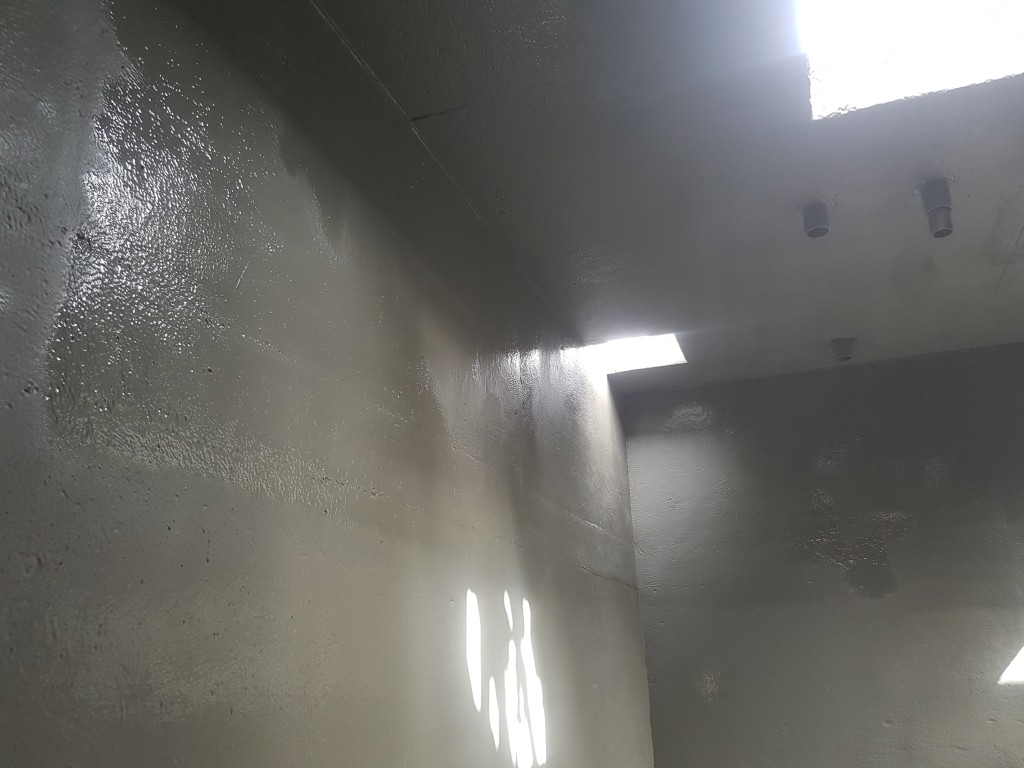

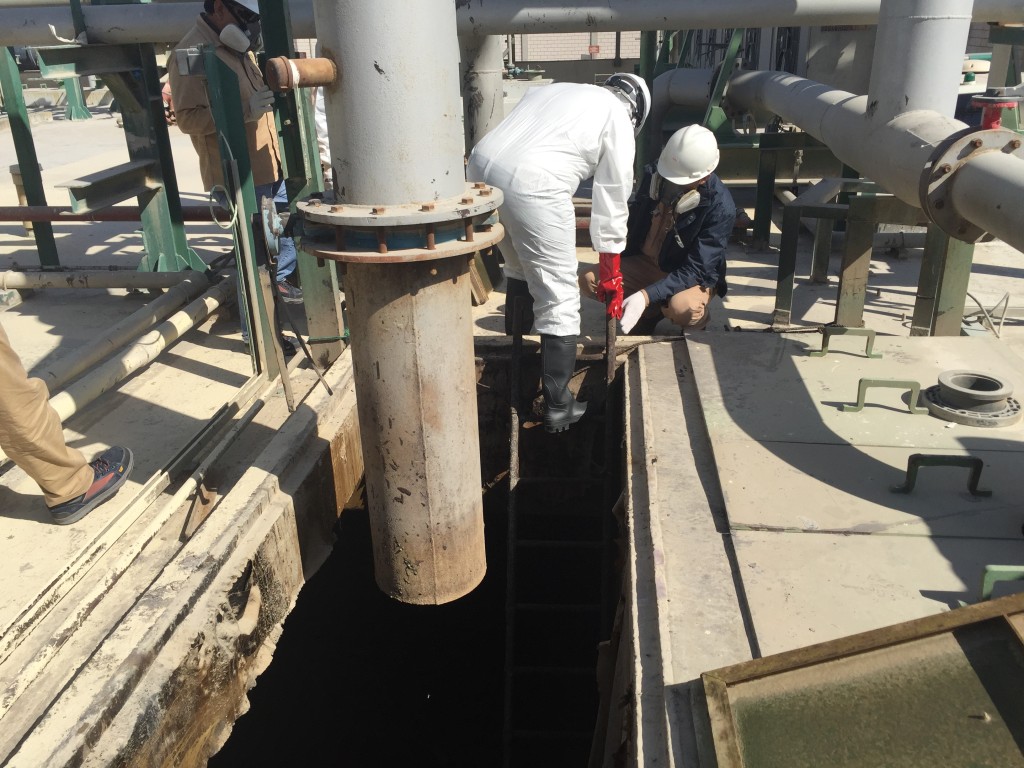

DELTAShield HP 400 was used for lining of 24 below ground concrete tanks. The Waster Water Recycling Plant had previously used another coating system which had shockingly failed to provide chemical resistance for the harsh chemicals used in the tanks. DELTA Coatings International went through a lot of tests towards chemical resistance and finally confirmed for the client to go ahead with DELTAShield HP 400. The applicator was instructed to remove the old liner, shot blast the entire concrete surface, seal all the bug holes and cracks, apply DELTAShield HP 400 at 4 mm thickness in one go to provide a seamless coating solution. Pull off tests after a week confirmed the bonding to the substrate was above 3.5 mpa which was more than satisfying for the client.

DELTAShield HP 400 is an instant curing, spray applied, seamless, and flexible protective membrane. DELTAShield HP 400 sits at the top of DELTA`s high performance coatings range and is suitable for use in a wide range of demanding applications requiring abrasion, impact and chemical resistance.

DELTAShield HP 400 is an excellent primary and secondary containment membrane providing seamless, instant curing, flexible containment solutions that require a higher performance level than standard waterproofing membranes. DELTAShield HP 400 is an ideal lining for abrasive liquid containment, industrial, chemical and impact applications.

The concrete surface was first prepared with DELTAPrime 2K SF Primer and DELTAPrime Filler.